|

In particular, the non-destructive testing of concrete (NDT) comprises the following tasks and equipment:

1. Finding the compressive endurance of concrete by using the following equipment:

- CONCRETE TESTER DIGI SCHMIDT

- SCHMIDT MATERIAL TEST HAMMER TYPE P & N

// According to international standards: EN 12398/ ASTM C805/ BS 1881 Part202/ DIN1048 Part202/ UNE 83.307

2. Finding the corresponding compressive endurance values, according to the method of ultrasounds, by using the following device:

- TICO ULTRASSONIG INSTRUMENT

Also according to the method of nails' removal, by using the following instrument:

// According to international standards: ISO/DIS 8047/ BS 1881 Part201/ ASTM C 597/ NF P 18-556/ NBN B 15-229 /UNI 7997/9524 UNE 83308

Apart from the values of compressive endurance, the device TICO ULTRASSONIG INSTRUMENT or PUNDIT may also be used to find: homogeneity of concrete - cavities, cracks, deficiencies concrete and elastic limit might appear.

3. Measuring thickness of concrete with the instrument:

4. In order to find the reinforcement of the bearing structure we use the following equipment:

- REBAR LOCATOR PROFOMETER 3&5 της PROCEQ

- FEROSCAN RV10 της HILTI

// According to international standards: SIA 162/ DIN 1045/ DGZ fp B2 BS 1881: Part204

Also for a full clarification of of the reinforcements of nodes and foundations, we use the sounding endoscope GF8.

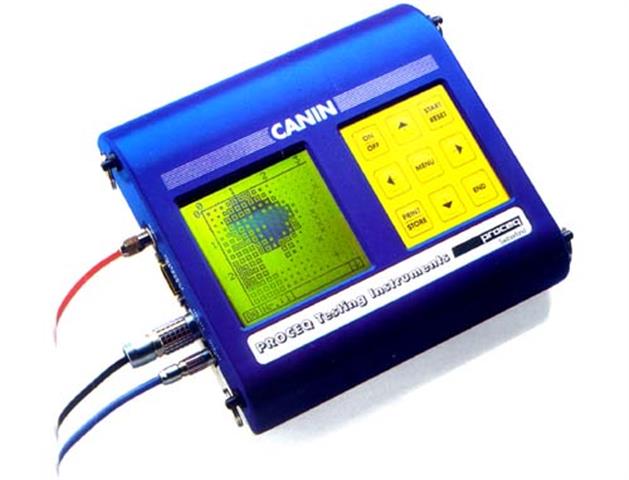

5. In order to find the reinforcements’ corrosion we use the device:

- CORROSION ANALYSING INSTRUMENT CANIN

// According to international standards: ASTM C876-80 /BS 1881 Part201 /SIA 2006 /DGZ fp B3 /UNI 10174

6. Finding the tensile resistance of concrete by using the following instrument:

- PULL-OFF TESTER της PROCEQ

// According to international standards: ISO 4524/ CEN/TC 125 /BS 1881 Part207 /ASTM C 4541 /ACI 503-30 DIN 1048 Part2

The combination of the above method and the use of phenolphthalein determine the depths of concrete carbonation (The results of this classical method contrast to the results of measurements of sounding endoscope GF8).

7. The dynamic charge trial forced on the building, allows us to get information about the dynamic characteristics and the structure's maximum responses, as well as its seismic vulnerability. So, t is proposed to strengthen the parts of the building, where there really is a problem (referring to those structural parts presenting pathological accelerations). All the above are carried out using the following instruments:

- KINEMETRICS STRONG MOTION ANALYST

- K2 DIGITAL RECORDER

- SEQUOIA

- Dynamic Stimulators: GFT9 1200EL & GFT500-350

8. Construction’s introduction in the of antiseismic evaluation program: MANDIS-GIBFIL.

9. Geotechnical - Geophysical determination of the effective stresses on the subsoil's foundation.

10. Collection of the information that concern the bearing structure of the building (reliability coefficient data KL3) and evaluation of the remaining earthquake capacity Vc according to Greek Guidelines (KAN.EPE.) by using the computer program SCADA PRO.

|

Scheduling the development of research projects, with our engineers’ assent.

Scheduling the development of research projects, with our engineers’ assent.